Chemical vapor deposition (CVD) is a widely used technique for depositing thin films of various materials,

including polycrystalline silicon (polysilicon). Polysilicon is commonly used in the semiconductor industry for integrated circuits and solar cells. In the CVD process for depositing polysilicon a precursor gas containing silicon is introduced into the reactor chamber. The most commonly used precursor gas for depositing polysilicon is silane(SiH4).

The precursor gas is activated by applying energy to break down the molecules and facilitate the chemical reaction. Typically, energy sources like thermal heating, plasma, or laser are used. The activated precursor gas reacts at the surface of the substrate, leading to the deposition of silicon atoms.

Temperature is a critical parameter that directly affects the growth and quality of the deposited polysilicon film. Accurate temperature measurement allows for precise control of the deposition process. By monitoring and adjusting the temperature, operators can optimize the growth rate, crystal structure, and electrical properties of the polysilicon film.

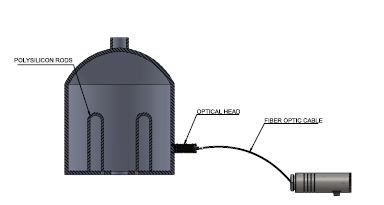

A fiber optic Ratio (two colour) pyrometer is used to measure the temperature of the substrate or the deposited polysilicon film. Fiber optic pyrometers are compact in size and have flexible optical fibers. They can be positioned in confined spaces or hard-to-reach areas. Fiber optic pyrometers are designed to withstand harsh operating conditions, such as high temperatures, vibrations, and chemical exposure. Ratio(two colour) technology provide accurate temperature measurements by comparing the intensities of two different wavelengths of light. This method reduces errors caused by factors such as emissivity variations, optical interferences, or dust on the surface being measured.

A 450C+ FO/PL is highly accurate ratio pyrometer with fibre optic and optical head. It has inbuilt temperature display and parameterising keys. Small spot size ensures high precision temperature measurement. A 450C+ FO/PL has dynamic temperature range 600…..1600°C,800….2500°C or 1000…..3000°C. Analog and digital output are available. A 450C+ series is providing with MODBUS protocol. It makes user easy to integrate to their existing system.