A pyrometer is a non-contacting device that intercepts and measures thermal radiation. This device can be used to determine the temperature of an object’s surface without contact to the surface. Advantage of Non-contact Sensors

- It records fast temperature within fractions of seconds.

- It does not influence the temperature and material of the target, so it is used to measure high temperatures (3000°C)

- It requires less maintenance, so it has longer life time.

- It can measure the temperature of the moving object.

- With the help of non-contact sensors, measurements can be taken for hazardous or physically inaccessible objects (e.g. high-voltage parts and great measurement distance).

- There is no risk of contamination and no mechanical effect on the surface of the object.

History of Pyrometers

The first pyrometer was created by the potter Josiah Wedgwood, who needed a way to accurately measure the temperatures inside his kilns. Initially, he used the color change of clay that had been fired at known temperatures as a reference. This method evolved into measuring how much pieces of clay shrank after being heated, which also provided clues about the kiln’s temperature. Over time, the technique further developed to involve the expansion of metal bars as a means of gauging heat.

The leap to modern pyrometry happened in the early 20th century, thanks to L. Holborn and F. Kurlbaum, who in 1901 introduced the first disappearing filament pyrometer. This innovative device worked by aligning a heated filament with the target object until the filament appeared to blend into the background, becoming “invisible” to the observer. At this point, the temperature could be read off a scale, marking a significant advance in the ability to measure temperatures accurately and paving the way for the sophisticated pyrometers we use today.

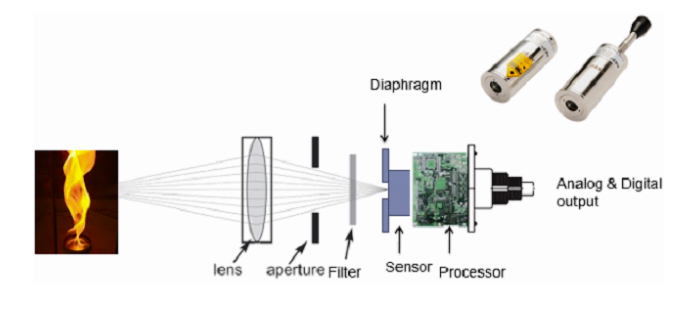

Basic Design, construction and operation of pyrometer

Pyrometer is any temperature-measurement device that includes a sensor and a read out. An optical system gathers the visible and infrared energy from an object and focuses it to the detector. The detector receives the photon energy from the optical system and converts it to an electric signal to drive a temperature display or control unit.

Infrared thermometers have various configurations and designs, which differ in optics, electronics, technology, size and housing. However, the method of signal processing is same.

Optical system, protection windows, spot size and measuring distance.

The detector and optical system are the major components in the pyrometer. So, they should be carefully selected to yield the optimum compromise based upon the conflicting parameters of price, accuracy, speed of response, and usable temperature range.

Optical system and protection windows

An optical system mostly consists of windows, lenses, and filters. A lens system can be used for particular wavelength ranges due to their material wavelength ranges. Usually for fixed focus optical instruments mirror system is used while for varying the focus instrument requires moving parts, which is less complicated in a lens system. So lens system is preferably used. The characteristics of the lens, filters and protection window material should be in accordance with spectral sensitivity of the sensor. With the help of filters, the transmission properties can be modified so that the unwanted wavelengths can be prevented from reaching the detector. They are placed in front of the detectors.

Spot size and measuring distance.

The common law of optics used in photography depends on the distance between the camera and the target increases. So, the distance between the camera and the target should be considered explicitly. The dimensions of the measured object determine the required spot size of the pyrometer. So, the target size should be larger than the detector spot (spot size). The distance ratio describes the size of the measuring spot at a certain distance. Also, the ratio of the distance of the measuring device from the target, and the diameter of the spot (D:S) describes the optical resolution. Better the optical resolution of the pyrometer smaller the target can be. To avoid errors in the measurements, the spot size should completely fill the object otherwise the sensor will read the other temperature radiation from the background.

Sighting techniques

There are several techniques for the adjustment of pyrometer which assist in capturing precise radiated temperature from the target. Some of them are described below

Through the lens sighting technique: In this technique, user looks at the object in the similar way as he looks through the camera.

Pilot lights/Laser-pointer: Halogen lamp, LED, or laser can be used as Pilot lights.

Detectors

Detectors play the vital role in any pyrometer. They are the radiation receivers which converts the received infrared radiation into electrical signals. These electrical signals are converted then displayed as temperature values by the electronic system. Detectors may be classified into two different categories viz. thermal detectors and quantum detectors. The behavior of thermal detectors is like any thermocouple. Quantum detectors works on the principle of photoelectric effect. Quantum detectors are faster than thermal detectors.

Electronics

The function of the electronics of the infrared thermometer radiation is to amplify, regulate, linearize and convert the signal from the detector to an electric signal (mV or mA) which is proportional to temperature. The output of the pyrometers can be viewed with analog and digital devices.

Analog devices

In portable thermometers measured temperature (signal) is displayed on the LCD. However, high precision LED indicator for non-contact temperature measurement is also being used. With indication of measured temperature user can easily parameterize a connected digital pyrometer without any PC.

Digital devices

By connecting the pyrometer output to some suitable software (via PC) the digital output can be obtained. The pyrometer can communicate with PC using RS232 or RS485. RS 232 is used only for short distances including electromagnetic interferences which affect the transmission. RS485 is well suited for long distance transmission. Standard on PC is RS232, so a converter is used which converts RS485 to RS232.

Thermographic solutions are completed with software for the online video display and recording of fast thermodynamic processes with manifold tools for picture analysis. Comfortable transfer and management of data from the infrared pyrometer as well as subsequent analysis of the data support the processing of the temperature results. Some of the functions available in the software are discussed below:

- Target emissivity: It can set the emissivity of the target.

- Peak picker: It locates the maximum temperature of the target temperature value from specified number of stored real temperatures in the sensor memory. Once the peak temperature is determined, its value will be transmitted constantly even at out-of-range condition till a new picker process finishes.

- Switch off Level: Ratio pyrometer shows true temperature even when the target is partially visible. The user can adjust this value, so when temperature of object is below this limit, the pyrometer will stop temperature measurement.

- Response Time: This function is used to set the response time of the pyrometer. It is adjustable from 20 ms to10 seconds.

- Record View: This option provides data logging. The temperature and Emissivity read by both the pyrometer with time and date is displayed.

- Spot size calculation: It calculates the spot size or Actual working Distance of the Pyrometer. This option in the software can calculate the spot size for real working distance corresponding to the value of actual working distance.

- Analog scale: User can select the sub-range within the basic range of Pyrometer. Analog output will automatically adjust to the selected range.

- Change sensor type: This parameter display pyrometer sensor type and user can also change two color sensors to single and vice versa within the same software.

Calibration

To achieve a reasonable level of accuracy, new pyrometers should be properly calibrated. Initial calibration is likely to be performed by the manufacturers. But for the most qualitative measurements periodic recalibration is required.

How Does A Pyrometer Work

Temperature is the most important physical quantity which predicts the condition of a product, both in manufacturing and in quality control. Pyrometer works on the principles of black body radiation.

The average or bulk properties of electromagnetic radiation interacting with matter are systematized in a simple set of rules called radiation laws. These laws are applied when the radiating body is a blackbody radiator. Usually, blackbody conditions apply when the body (radiator) has very weak interaction with the surrounding environment and the state of equilibrium is considered. In simple terms, a Black Body is an object that absorbs all electromagnetic radiation that falls onto it. In this, neither radiation passes through it nor reflected. The total emittance from a black body including all wavelengths is directly proportional to the Fourth power of its temperature. This temperature is called Brightness Temperature

Types of Pyrometers

Generally, pyrometers can be classified in three types which are:

- Single Color Pyrometer

- Two Color Pyrometer/ Ratio Pyrometer

- Multi Wavelength Pyrometer

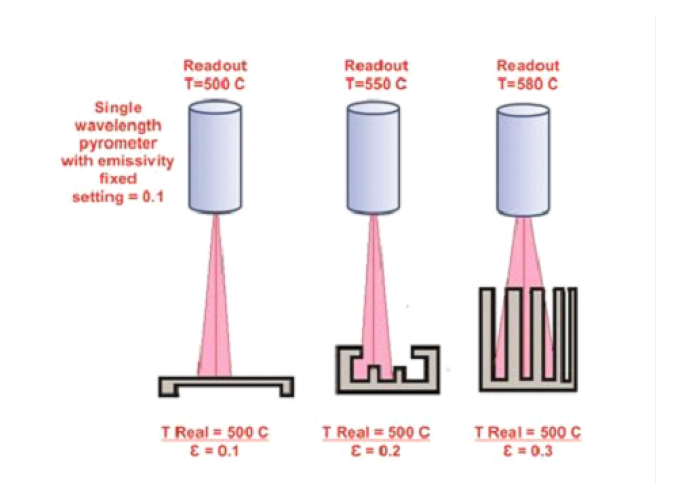

Single color pyrometers

Single colour pyrometer is working on a specific wavelength and is accuracy of measurement is dependent on the emissivity of the object.

These pyrometers operate over a narrow range of wavelengths. The spectral response of these pyrometers is usually less than 1 micron. They are normally used for measuring glass at 5.14 μm. Metals can also be measured as their rate of emissivity is high only in a narrow band. The spectral response of the device depends on the type of the detector used. For an instance, the response of a pyrometer with a silicon cell detector is around 0.9 – 1.1 microns. These pyrometers can work on selected wavelength range with the help of filters. But for this more sensitive detectors and advances in signal amplifiers are required.

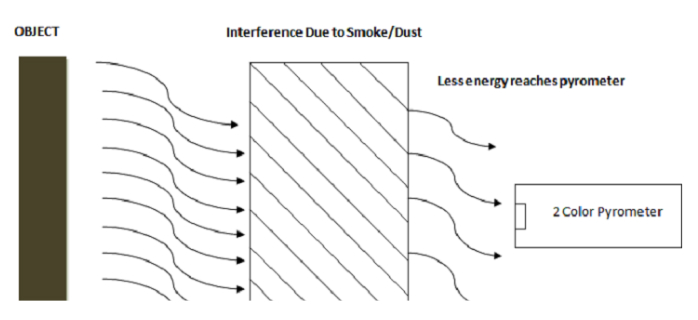

Ratio radiation pyrometers (two color pyrometers)

This pyrometer measures the radiated energy of an object between two narrow wavelength bands and then calculates the ratio of the two energies. This ratio is the function of the temperature of the object. This is also called as two-color pyrometer because the two wavelengths corresponded to different colors in the visible spectrum. Even if the object does not fully cover the spot the output signal will not change. Also, the temperature measurement is independent of emissivity, so the errors caused by the emissivity variation, surface finish, and energy absorbing materials (e.g., smoke, smog, water vapor, etc.) between the pyrometer and the target can be minimized or removed. It is used for measuring high temperature (e.g., molten metal).

Multi wavelength pyrometers

This type of pyrometer is capable of measuring more than two wavelengths. They are also called spectropyrometers. Here instrument compares all the measured values and then decides where the accurate temperature lies. It is also an expert-system multi-wavelength pyrometer has been able to overcome many well-known difficulties of pyrometry, including unknown, changing, and/or spectral dependence of emissivity as well as environmental absorption of radiation.

What factors should be considered when setting up a pyrometer system?

When setting up a pyrometer system in your industrial process, there are several important factors to consider:

- Temperature Range: Determine the specific temperature range that needs to be measured for your application. This will help you select a pyrometer that is capable of accurately measuring the desired temperature range.

- Distance and Specific Requirements: Consider the distance between the pyrometer and the object you want to measure. Additionally, identify any specific requirements unique to your industrial measurement application that might influence the selection of the appropriate pyrometer.

- Pyrometer Selection: With the knowledge of your measurement requirements, choose the correct pyrometer. Keep in mind that there are various options available, each with different configurations suited for specific industrial applications. Consider seeking assistance from a specialist who can provide expertise and guidance in selecting the most suitable pyrometer for your needs.

- Proper Installation: The installation of the pyrometer system requires the expertise of a specialist to ensure proper and secure mounting. It is essential to eliminate any potential sources of vibrations that could affect the accuracy of temperature measurements. Proper alignment of the pyrometer with the targeted object is crucial for achieving precise temperature readings.

- Integration with Plant Control System: The pyrometer system should be integrated with the plant control system to enable ongoing monitoring. Connect the pyrometer(s) to your control system and configure it to receive the pyrometer’s signal. This integration allows the control system to utilize the temperature measurements for effective process control.

What are the key features of AST’s non-contact type IR-based Pyrometer?

The AST non-contact IR Pyrometer is super versatile, working perfectly for temperatures from cold to super hot (0°C to 3000°C). It’s really quick, giving you accurate temperature readings in just a blink. Thanks to a handy laser pointer, you can easily aim at exactly where you want to measure. Plus, it connects in many ways, including USB, Bluetooth, and serial ports, so you can use it with different devices. Even when measuring temperatures in tricky situations like plasma, this pyrometer gets it right, using a special light wave to ensure the reading is spot on.

FAQ

What is the role of a pyrometer system in lab-grown diamond production?

In lab-grown diamond production, a pyrometer system is like a smart thermometer. It carefully measures how hot things get, which is super important for making diamonds in a lab. This helps make sure the diamonds grow just right, by keeping the temperature perfect during the whole process. It’s like baking a cake; you need the right heat to get the best results!

Why use a Pyrometer in Temperature Measurement?

Using a pyrometer for measuring temperature is super helpful because it can measure heat without touching the thing you’re checking. This is great for really hot or hard-to-reach places. Pyrometers give quick and accurate readings, making them perfect for jobs where you need to know the temperature fast and safely.

What are the advantages of using non-contact temperature measuring devices like pyrometers?

Non-contact temperature measuring devices, such as pyrometers, offer several advantages. They can record fast temperature within fractions of seconds. They do not influence the temperature and material of the target, making them suitable for measuring high temperatures (e.g., up to 3000°C). They require less maintenance, resulting in a longer lifetime. They can measure the temperature of moving objects or physically inaccessible objects, such as high-voltage parts and objects with great measurement distance. Additionally, there is no risk of contamination or mechanical effect on the surface of the object.

Why are pyrometers used in many industries?

Pyrometers are used in many industries because they can measure temperature without having to be in direct contact with the item being measured.

What role does temperature play in industrial processes?

Temperature plays a major role in certain industrial applications. Accurately measuring temperature during the process can be the difference between success and failure in a run.