Introduction

In industrial processes, precision and accuracy are paramount. One crucial tool that ensures these qualities is the pyrometer. Infrared Pyrometers are temperature measurement devices used in various industries, from manufacturing to energy production. But the key to their effectiveness lies in proper installation.

This guide will walk you through the essential steps and considerations for installing pyrometers in industrial settings. We’ll cover everything from selecting the right location to addressing safety measures and common challenges. By the end of this article, you’ll clearly understand how to install pyrometers effectively and safely.

Understanding the Importance of Pyrometers in Industrial Applications

Before diving into installation procedures, let’s take a moment to understand why pyrometers are so crucial in industrial applications.

- Pyrometers at Work: Pyrometers are employed in various industrial processes to measure temperatures without direct contact. This non-contact method is precious in scenarios where traditional thermocouples or contact sensors might be impractical or unsafe. Industries such as manufacturing, metal processing, and energy production rely on pyrometers for precise temperature measurements.

- The Impact of Accuracy: Even a slight temperature variation can have significant consequences in these industrial settings. Accurate temperature measurements are essential for ensuring product quality, process efficiency, and, most importantly, safety. For instance, in a steel mill, precise temperature control is vital for producing high-quality steel while minimizing waste.

- Pyrometers and Process Optimization: Pyrometers are critical in optimizing industrial processes. Providing real-time temperature data allows operators to make informed decisions, adjust parameters, and achieve consistent results. This improves product quality and reduces energy consumption and operational costs.

Pre-Installation Preparation

Installing a pyrometer begins with thorough preparation. Skipping this step can lead to errors and inefficiencies down the line. Let’s explore the key aspects of pre-installation preparation.

- Identifying the Measurement Point: The first step is identifying where you need temperature measurements. Consider the specific application and the factors affecting temperature. This might be a furnace, a conveyor belt, or a pipeline.

- Selecting the Appropriate Pyrometer Model: Not all pyrometers are created equal. Select a pyrometer model that suits your specific industrial application. Factors to consider include the expected temperature range, the emissivity of the materials being measured, and the desired level of accuracy.

- Gathering Necessary Tools and Equipment: Ensure you have all the tools and equipment required for the installation. This includes mounting brackets, cables, and other accessories for your chosen pyrometer model.

- Location Selection: Selecting the right location for your pyrometer is critical. Consider the following factors:

- Line of Sight: Ensure that the pyrometer has a clear line of sight to the target area. Obstructions can lead to inaccurate readings.

- Accessibility: Choose a location that allows easy maintenance and calibration access.

- Safety: Ensure the chosen location is safe for installation and future operation.

- Ambient Temperature and Atmospheric Conditions: Industrial environments can be harsh, with extreme temperatures and varying atmospheric conditions. Take these factors into account:

- Ambient Temperature: Consider the ambient temperature around the pyrometer. Extreme temperatures can affect the pyrometer’s performance.

- Atmospheric Conditions: Smoke, dust, and humidity can impact measurement accuracy. Install appropriate shields or filters to mitigate these effects.

Safety Measures During Pyrometer Installation

Safety should always be a top priority when working in industrial settings. Here are some critical safety measures to follow during pyrometer installation:

- Personal Protective Equipment (PPE): Ensure that all personnel involved in the installation wear the necessary PPE. This typically includes safety glasses, gloves, and appropriate clothing.

- Lockout/Tagout Procedures: If the installation involves working on equipment or machinery, follow lockout/tagout procedures to ensure that power sources are safely disconnected and clearly marked.

- Working in Confined Spaces: In some cases, pyrometer installation may require working in confined spaces. If so, follow strict safety protocols for confined space entry, including proper ventilation and rescue plans.

Best Practices for Pyrometer Installation

Now that you’ve completed the pre-installation preparation and addressed safety concerns, it’s time to proceed with the installation. Here are the best practices for pyrometer installation:

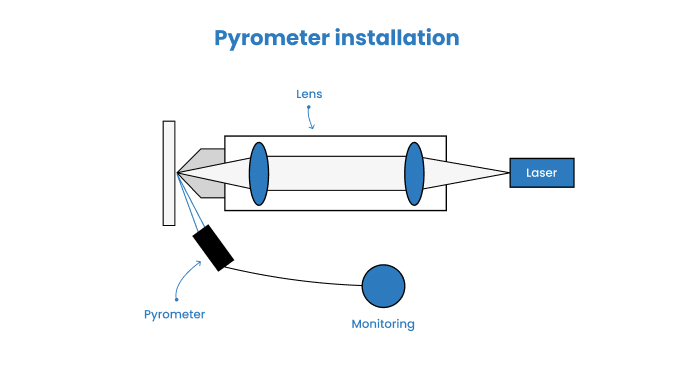

Mounting the Pyrometer

- Ensure the mounting bracket is securely attached to the installation location.

- Mount the pyrometer on the bracket, ensuring it is level and stable.

- Double-check that the pyrometer has an unobstructed line of sight to the target area.

Correct Positioning of the Pyrometer

- Position the pyrometer at the appropriate distance from the target area. Refer to the pyrometer’s manual for guidance on the optimal distance.

- Angle the pyrometer so that it focuses on the target area effectively.

- Consider the target’s emissivity, as it can affect measurement accuracy.

Ambient Temperature Considerations

- Be mindful of the ambient temperature in the installation area. Extreme heat or cold can impact the pyrometer’s performance.

- Some pyrometer models have built-in temperature compensation features to account for temperature variations.

Atmospheric Conditions Affecting Measurement Accuracy

- Install shields or filters to protect the pyrometer from environmental factors like smoke, dust, or humidity.

- Regularly clean and maintain these protective elements to ensure accurate readings.

Wiring and Connections

- Follow the manufacturer’s guidelines for wiring and connections. Use appropriate cables and connectors.

- Double-check the electrical connections to ensure they are secure and correctly configured.

Calibrating the Pyrometer for Accurate Measurements

- After installation, calibrate the pyrometer to ensure accurate temperature measurements.

- Follow the calibration procedures outlined in the pyrometer’s manual or consult the manufacturer for guidance.

- Regularly schedule recalibration to maintain accuracy over time.

Challenges and Solutions

Even with careful planning and adherence to best practices, challenges can arise during pyrometer installation in industrial settings. Here are some common challenges and their solutions:

High Temperatures

- Challenge: Installing pyrometers in extremely high-temperature environments can be challenging due to the risk of heat-related damage.

- Solution: Use specialized high-temperature pyrometer models designed for such conditions. Implement proper heat shielding and cooling mechanisms if necessary.

Harsh Conditions

- Challenge: Industrial environments often have harsh conditions, such as exposure to chemicals, vibrations, or corrosive materials.

- Solution: Choose pyrometers with robust designs and materials that can withstand these conditions. Implement regular maintenance routines to prevent corrosion.

Accessibility Issues

- Challenge: Some installation locations may need help to access for maintenance and calibration.

- Solution: Plan for accessibility during the initial installation phase. Consider remote monitoring options for hard-to-reach areas.

Maintenance and Calibration

Once your pyrometer is installed and operational, it’s essential to prioritize maintenance and calibration to ensure consistent accuracy. Here’s how to approach maintenance and calibration:

Regular Maintenance

- Develop a maintenance schedule that includes routine inspections and cleaning of the pyrometer and its components.

- Check for any signs of wear or damage and replace parts as needed.

- Keep records of maintenance activities and observations.

Calibration Schedule

- Determine how frequently your pyrometer needs calibration based on its usage and environmental conditions.

- Follow the manufacturer’s recommended calibration procedures or consult with a qualified technician.

- Document calibration results to track the pyrometer’s accuracy over time.

Emergency Troubleshooting

- Have a plan for addressing any sudden issues or malfunctions with the pyrometer.

- Train personnel to perform basic troubleshooting and contact technical support or a qualified technician when needed.

In industrial settings, installing pyrometers is a critical step in ensuring processes’ efficiency, safety, and quality. Following the best practices and safety measures outlined in this guide, you can install pyrometers effectively and confidently.

Remember that accuracy matters. A well-installed and properly maintained pyrometer can make all the difference in achieving consistent results, optimizing processes, and ensuring the safety of your industrial operations.

By prioritizing precision and safety, you contribute to the success and longevity of your industrial processes, benefiting both your organization and the broader industrial community.