Introduction to Pyrometers

A pyrometer is an instrument used to measure high temperatures without directly contacting the object being measured. It is commonly employed in various industries and manufacturing processes where accurate temperature measurements are essential. The word “pyrometer” is derived from the Greek words “pyro,” meaning fire, and “meter,” meaning measure.Pyrometers come in different types, including optical pyrometers and infrared pyrometers. These instruments employ other principles to measure temperature, allowing versatility in various applications. To learn more about the different types of pyrometers, you can refer to our article on types of pyrometers.

Importance of Non-Contact Temperature Measurement

Non-contact temperature measurement, facilitated by pyrometers, is crucial in many industrial and manufacturing processes. It offers several advantages over traditional contact-based temperature measurement methods:

- Safety: Non-contact temperature measurement eliminates the need for physical contact with hot surfaces, reducing the risk of accidents and ensuring personnel safety.

- Efficiency: Pyrometers allow quick temperature measurements without requiring time-consuming setup or waiting for the object to cool down. This efficiency is particularly valuable in fast-paced production environments.

- Remote Measurement: Pyrometers enable temperature measurement from a distance, making it possible to measure the temperature of objects that are difficult to access or in hazardous environments.

- Non-Destructive: Non-contact temperature measurement does not alter the measured object, making it suitable for delicate materials or processes where direct contact could cause damage.

- Wide Temperature Range: Pyrometers can measure temperatures ranging from a few degrees Celsius to several thousand degrees Celsius, depending on the specific instrument and its capabilities.

By utilizing pyrometers for non-contact temperature measurement, industries and manufacturers can enhance process control, improve product quality, and ensure the safety of their operations.

In the following sections, we will delve into the different types of pyrometers, their working principles, applications, and factors to consider when choosing the right pyrometer for specific requirements. Stay tuned to explore the fascinating world of pyrometers!

Understanding Infrared Pyrometers

In non-contact temperature measurement, infrared pyrometers play a crucial role. These devices are widely used in various industries to measure temperatures without physically touching the estimated object. This section will explore how infrared pyrometers work and discuss their advantages.

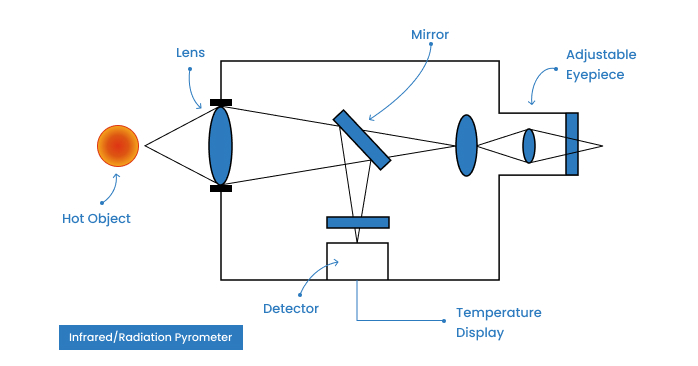

How Infrared Pyrometers Work

Infrared pyrometers work based on the principle of thermal radiation. All objects emit infrared radiation, and the intensity of this radiation is directly related to the object’s temperature. Infrared pyrometers use a lens to focus the infrared radiation emitted by the object onto a detector. The detector measures the intensity of the radiation and converts it into an electrical signal. This signal is then processed to provide an accurate temperature reading.

It is essential to consider the object’s emissivity to ensure accurate measurements. Emissivity refers to the object’s ability to emit infrared radiation. Different materials have different emissivity values, and infrared pyrometers can be adjusted to account for these variations. Understanding emissivity and how it affects temperature measurements is crucial for obtaining accurate results. For a more detailed explanation, refer to our article on what a pyrometer is

Advantages of Infrared Pyrometers

Infrared pyrometers offer several advantages over traditional contact temperature measurement methods. Some of the key benefits include:

- Non-Contact Measurement: Infrared pyrometers allow temperature measurement without physically touching the object, ensuring no interference or contamination.

- Fast and Efficient: Infrared pyrometers provide instant temperature readings, allowing for quick and efficient monitoring of temperature changes.

- Wide Temperature Range: Infrared pyrometers can measure a wide range of temperatures, from extremely high temperatures in industrial processes to lower temperatures in manufacturing applications.

- Versatility: Infrared pyrometers can be used in various fields, including industrial processes, manufacturing, research, and development.

- Remote Operation: Many modern infrared pyrometers can be operated remotely, allowing for safe temperature measurement in hazardous or hard-to-reach areas.

- Minimal Maintenance: Infrared pyrometers are generally low-maintenance devices, requiring minimal calibration and upkeep.

Industries can benefit from accurate and efficient temperature measurements by utilizing infrared pyrometers. They are precious in applications where contact with the measured object is not feasible or desired. For more information on the different types of pyrometers and their specific applications, refer to our article on types of pyrometers. In the next section, we will explore the various applications of pyrometers in different industries and fields.

Applications of Pyrometers

Pyrometers, specifically infrared ones, are widely used in various industries and manufacturing processes and are widely used as temperature-measuring tools. Let’s explore some of the key areas where pyrometers are commonly used:

Industrial Applications

In industrial settings, pyrometers are vital in temperature monitoring and control. They are extensively used in steel, glass, ceramics, and metal processing industries. Pyrometers enable precise temperature measurement without direct contact, ensuring the safety of workers and equipment in high-temperature environments. These devices allow for real-time monitoring and help maintain optimal operating conditions. For example, in a steel mill, pyrometers are used to monitor the temperature during the steel production process, ensuring the desired quality and consistency of the final product.

Manufacturing Applications

Pyrometers are essential tools in manufacturing processes where temperature control is critical. They are used in heat treatment, soldering, brazing, and welding applications. By accurately measuring the temperature, pyrometers ensure that the required temperature thresholds are reached and maintained, resulting in high-quality and reliable products.

Other Fields Where Pyrometers are Used

Besides industrial and manufacturing applications, pyrometers are helpful in various other fields. They are commonly employed in research laboratories, environmental monitoring, and the culinary industry for precise temperature measurements during cooking. Pyrometers are also used in kilns, ovens, and furnaces to monitor and control the temperature for optimal performance and energy efficiency.

The versatility and accuracy of pyrometers make them indispensable tools in various applications. By providing non-contact temperature measurement, pyrometers enable efficient and precise temperature monitoring in environments where direct contact measurement may not be feasible or safe.

To choose the right pyrometer for your specific application, it’s essential to consider factors such as temperature range, accuracy, response time, and other specific requirements.

In the next section, we will explore the factors that should be considered when choosing a pyrometer, ensuring you make an informed decision based on your needs and requirements.

Factors to Consider When Choosing a Pyrometer

Several essential factors must be considered when selecting a pyrometer for your temperature measurement needs. These factors will help you choose the right pyrometer to accurately and reliably measure temperatures in your specific application. The key factors to consider are temperature range, accuracy and precision, response time, and other considerations.

Temperature Range

One of the primary considerations when choosing a pyrometer is the temperature range it can measure. Different applications require pyrometers that can accurately measure temperatures within specific ranges. Some pyrometers are designed for lower temperature ranges, while others are suitable for extremely high temperatures. Selecting a pyrometer that can cover the entire temperature range of your intended application is essential.

Accuracy and Precision

Accuracy and precision are crucial factors when it comes to temperature measurement. The accuracy of a pyrometer refers to how close its measurements are to the actual temperature, while precision relates to the repeatability of those measurements. Choosing a pyrometer that offers high accuracy and precision is essential to ensure reliable and consistent temperature readings.

When comparing pyrometers, pay attention to the stated accuracy and precision specifications provided by the manufacturer. These specifications will give you an idea of the pyrometer’s performance and suitability for your application. It is also worth considering the calibration requirements of the pyrometer to maintain its accuracy over time.

Response Time

The response time of a pyrometer is another critical factor to consider. It refers to how quickly the pyrometer can provide an accurate temperature reading after exposure to a new temperature source. Depending on your application, you may require a pyrometer with a fast response time to capture rapid temperature changes or a slower response time for stable temperature measurements. Understanding the response time of a pyrometer is essential to ensure that it can meet the requirements of your specific application. Manufacturers typically provide response time specifications for their pyrometers, allowing you to choose the one that best suits your needs.

Other Considerations

In addition to the above factors, other considerations may influence your choice of a pyrometer. These include the pyrometer’s size, durability, interface options, and additional features such as data logging capabilities or connectivity options. It is essential to evaluate these factors based on your specific requirements and the environment in which the pyrometer will be used.

You can choose a pyrometer that meets your needs by carefully considering the temperature range, accuracy and precision, response time, and other relevant factors. Remember that different applications may have unique requirements, so it is essential to select a well-suited pyrometer for your intended purpose.

Tips for Using Pyrometers Effectively

To ensure accurate and reliable temperature measurements, it’s important to use pyrometers effectively. Here are some essential tips to consider when using pyrometers:

Proper Calibration and Maintenance

Calibration is crucial for the accurate operation of pyrometers. Regularly calibrating your pyrometer helps maintain its accuracy and ensures that it provides precise temperature measurements. It’s recommended to calibrate your pyrometer using a known reference temperature source. This will help identify any deviations and allow for necessary adjustments.

In addition to calibration, proper maintenance of the pyrometer is essential. Keep the lens clean and free from any debris or contaminants impacting its accuracy. Regularly inspect the pyrometer for any signs of damage or wear and tear. If you notice any issues, such as a cracked lens or malfunctioning display, it’s essential to address them promptly.

Understanding Emissivity

Emissivity is a fundamental concept when using pyrometers. It refers to the ability of an object to emit thermal radiation. Since pyrometers measure temperature based on the radiation emitted by an object, understanding the emissivity of the estimated material is crucial for accurate results.

Different materials have different emissivity values, which can impact the accuracy of temperature measurements. It’s essential to consult reference tables or utilize an adjustable emissivity setting on your pyrometer to account for variations in emissivity. This will help ensure accurate temperature readings, particularly when measuring the temperature of different materials.

Best Practices for Measurement

To achieve the best results when using pyrometers, it’s essential to follow best practices for measurement. Here are some key considerations:

- Distance: Maintain the recommended distance between the pyrometer and the object being measured. This distance can vary depending on the specific pyrometer model and the target material. Following the manufacturer’s guidelines will help ensure accurate measurements.

- Target Area: Ensure the pyrometer is aimed at the correct target area on the measured object. The target area should represent the average temperature of the object and should be free from any obstructions or reflections that can impact the readings.

- Ambient Conditions: Be mindful of the ambient conditions when using a pyrometer. Factors such as ambient temperature, air movement, and dust or smoke can affect the accuracy of temperature measurements. Minimize these factors as much as possible to obtain reliable results.

- Temperature Range: Select a pyrometer suitable for your application’s temperature range. Different pyrometers have different temperature ranges, and using a pyrometer beyond its specified scope can lead to inaccurate results. Refer to the manufacturer’s specifications to ensure the pyrometer fits your intended measurement range.

By following these tips, you can maximize the effectiveness of your pyrometer and obtain accurate temperature measurements in various applications. Consider the manufacturer’s guidelines and specifications for specific recommendations regarding your pyrometer model.