Introduction

Welcome to the fascinating world of thermal imaging! In simple terms, thermal imaging is a technology that allows us to see temperature variations. Imagine having a “heat vision” that can see through darkness, fog, and specific materials. Sounds like something out of a sci-fi movie, right? But it’s a reality and an increasingly important one in various industries.

From healthcare and manufacturing to construction and agriculture, thermal imaging is becoming an indispensable tool. Why? Because it provides invaluable data that other forms of imaging just can’t offer. It helps us make better decisions, enhances safety, and even saves costs in the long run.

So, what’s this article about? We’re diving deep into the various thermal imaging applications across different sectors. Whether you’re a professional in one of these fields or just someone interested in cutting-edge technology, this article aims to shed light on how thermal imaging camera is making waves in multiple industries.

What is Thermal Imaging?

So, let’s get straight to the point: What exactly is thermal imaging? In the simplest terms, it’s a technology that lets us see heat. Yep, you read that right—thermal imaging captures the heat energy emitted by objects and turns it into a visible image. It’s like viewing the world through a ‘heat lens.’

The Science Behind It

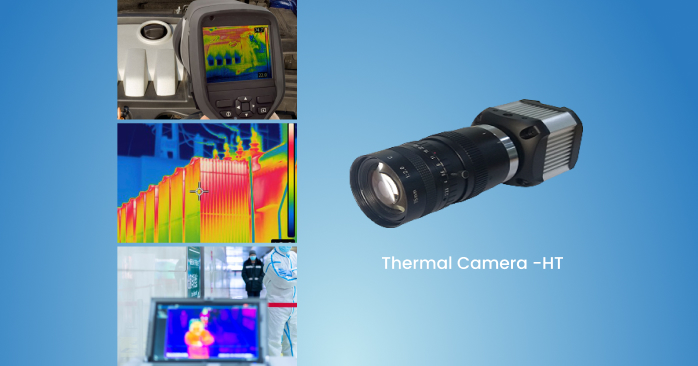

I will only go a little deeper into the scientific jargon. Still, a little background is necessary to understand a thermal Camera? Everything around us emits some level of infrared radiation—yes, even ice. This radiation is just heat energy that’s invisible to our eyes. Thermal imaging devices have special sensors that detect this invisible heat energy. They then convert it into an image of different colors, each representing a specific temperature range. Hotter objects appear in shades of red and yellow, while cooler ones appear in blues and greens.

Common Devices that Use Thermal Imaging

You’d be surprised at how many gadgets and systems use this tech. The most familiar one is the thermal imaging camera, often used in search and rescue operations. But it doesn’t stop there. Thermal imaging is used in drones for aerial surveys, in smartphones for various applications, and even in cars to enhance night driving. And let’s remember its role in medical diagnostics, where it helps to identify areas of inflammation or poor circulation.

Key Components of a Thermal Imaging System

Alright, now that we know what thermal imaging is, let’s talk about what makes it tick. A thermal imaging system isn’t just one piece of technology; it’s a well-coordinated ensemble of different components. Here are the stars of the show:

- Infrared Sensors: Consider these as the ‘eyes’ of the thermal imaging system. Infrared sensors do the heavy lifting by capturing invisible infrared radiation (or heat) from objects. These sensors are highly sensitive to temperature changes, even the tiniest ones.

- Display Screen: Once the infrared sensors capture the heat data, where does it go? Straight to the display screen, which serves as the ‘face’ of the system. This screen translates the captured data into an image that’s easy for us to understand. Different colors represent different temperatures, allowing us to ‘see’ the heat.

- Software: Last, we have the software—the ‘brain’ behind the operation. The software processes the raw data from the infrared sensors and turns it into something meaningful. It often comes with features like zoom, tracking, and even alerts for extreme temperatures. Some advanced systems offer analytics capabilities, making it easier to interpret the data for specific industry needs.

How They Work Together

So, how do these components work together? It’s a pretty streamlined process:

- The infrared sensors detect the heat.

- This data is sent to the software for processing.

- The processed data is displayed on the screen as a thermal image.

It’s a continuous loop of capturing, processing and displaying, all happening in real-time. And that, folks, is how a thermal imaging system works.

General Applications of Thermal Imaging

Now that we’ve got the basics down let’s talk about why thermal imaging is such a big deal. This technology isn’t confined to one industry or application; it’s versatile and invaluable in many scenarios. Here are some of the general areas where thermal imaging shines:

Safety and Surveillance

First up is safety and surveillance, and let me tell you, thermal imaging is a game-changer here. Traditional cameras can’t see through smoke or darkness, but thermal cameras can. This makes them ideal for monitoring large areas, be it a factory floor or a parking lot, especially in low-light conditions. They’re also widely used by law enforcement agencies to track suspects or find missing persons.

Environmental Studies

If you’re into nature and the environment, you’ll find this interesting. Thermal imaging helps researchers monitor wildlife without disturbing their natural behaviors. It’s also used to study heat patterns in the atmosphere, which can be crucial for understanding climate change.

A Glimpse into Industry-Specific Applications

We’ve covered some broad applications, but this is just the tip of the iceberg. Each industry has unique challenges and needs, and thermal imaging is versatile enough to adapt. Whether it’s quality control in manufacturing or crop monitoring in agriculture, this tech has a role. Curious to know more? Keep reading as we dive into how thermal imaging is used in specific industries.

Thermal Imaging in Manufacturing

Manufacturing is like the backbone of our modern world, creating everything from gadgets to cars. And in a setting where precision and efficiency are key, thermal imaging has proven to be an invaluable ally. Let’s explore how:

- Quality Control: Thermal imaging cameras can quickly scan products or components to meet quality standards. For instance, in electronics manufacturing, thermal cameras can spot soldering defects or electrical issues that are invisible to the naked eye. This speeds up the QC process without sacrificing accuracy.

- Machinery Maintenance: Factories are filled with machines crucial for production, and any downtime can be costly. That’s where thermal imaging comes in handy. By scanning the machines, you can identify parts that are overheating and might soon fail. This enables proactive maintenance, reducing the risk of unexpected breakdowns and keeping the assembly line moving smoothly.

- Safety Measures: Safety is non-negotiable in a manufacturing environment. Thermal imaging can play a significant role in fire prevention by monitoring areas for hotspots that could potentially lead to a fire. This provides an extra layer of safety, allowing for timely interventions before anything gets out of hand.

Thermal Imaging in Construction

If you think construction is all about bricks, cement, and manual labor, think again. Modern construction is as much about technology as it is about materials, and thermal imaging has a significant role. So, how is this technology used in the world of construction? Let’s take a look.

- Building Analysis: The first step in any construction project is to understand what you’re working with, and thermal imaging provides invaluable insights here. By scanning a building, you can identify thermal weak spots that could indicate structural flaws or areas where energy is being wasted. This information is crucial for planning renovations or new construction projects to meet energy efficiency standards.

- Insulation Quality: Insulation is the unsung hero of any well-constructed building, keeping us warm in the winter and cool in the summer. Thermal imaging can quickly assess the quality of insulation by detecting areas where heat is escaping. This allows for targeted fixes, ensuring that a building is as energy-efficient as possible, which is not just good for the planet but also for your wallet.

- Detecting Structural Issues: Sometimes, issues like water leaks or foundational cracks are hidden from the eye but can cause significant problems. Thermal imaging can detect temperature differences that may indicate such structural issues, allowing for early intervention before things get worse.

Thermal Imaging in the Automotive Industry

Cars have come a long way from being mere modes of transportation. Today, they’re packed with technology designed to make driving safer, more efficient, and more comfortable. One of the technologies making a difference is thermal imaging. Let’s delve into how it’s shaping the automotive industry.

- Driver Safety: First on the list is driver safety, and it’s a big one. Night driving can be risky due to limited visibility, but thermal imaging can change that. Some high-end vehicles now come with thermal imaging systems that can detect pedestrians, animals, or objects on the road far beyond the reach of your headlights. This gives drivers more time to react, reducing the risk of accidents.

- Engine Monitoring: Cars are complex machines, and many can go wrong under the hood. Regular inspections are good, but having real-time data is even better. Thermal imaging can monitor the engine and other key components for overheating or other issues. This can be especially helpful in commercial vehicles on the road for extended periods and can’t afford unexpected breakdowns.

- Research and Development: The automotive industry is always in a state of evolution, looking for ways to improve vehicle performance and safety. Thermal imaging plays a role here, too. Engineers use thermal cameras to study how vehicle parts respond under various conditions. This information helps in designing cars that are not only more efficient but also safer.

Challenges and Limitations

Now, as much as we’d love to paint thermal imaging as a miracle technology, it’s important to acknowledge that it’s not without its challenges. So, let’s get real for a moment and talk about some of the hurdles and limitations of implementing thermal imaging.

- Environmental Factors: One of the first things to consider is the impact of environmental conditions. Factors like rain, fog, or extreme heat can affect the accuracy of thermal imaging systems. For example, heavy rain can cool surfaces quickly, making it difficult for the sensors to get an accurate read on temperature variations.

- Cost: High-quality thermal imaging systems are costly. While prices have declined, the initial investment can still be a significant factor for small businesses or individual users. Ongoing maintenance and software updates can also add to the overall expense.

- Limited Range: Thermal imaging is great for close to mid-range detection, but it’s not ideal for long-range applications. The farther you are from the object, the less accurate the temperature reading will be. This limits its use in scenarios where long-range detection is crucial.

- Interpretation of Data: The images produced by thermal cameras are not always straightforward. They require trained personnel to interpret them accurately. Incorrect interpretation can lead to false positives or missed issues, defeating the purpose of using this technology in the first place.

In conclusion, Thermal imaging is undeniably reshaping various industries, offering a unique blend of safety, efficiency, and innovation. From healthcare diagnostics to ensuring automotive safety, its applications are as diverse as they are impactful. However, like any technology, it comes with its own set of challenges—cost, environmental limitations, and the need for specialized training. But as we move forward, improvements and adaptations are likely to make this tool even more indispensable. Simply put, thermal imaging is not just a trend; it’s a transformative technology with a promising future.