The High-Temperature Thermal View Furnace Camera System is an innovative and indispensable industrial monitoring solution, purpose-built to provide real-time visual and thermal information in high-temperature environments like furnaces, kilns, and various industrial processes. With its cutting-edge features, this advanced system is designed to enhance process efficiency, safety, and control for industrial operators.

One of the key strengths of this system is its high-temperature resistance, ensuring it operates reliably even in harsh and extreme industrial settings. Equipped with state-of-the-art infrared technology, the camera captures precise thermal data, allowing operators to accurately monitor temperature variations in real-time. Simultaneously, the integrated high-resolution camera delivers crystal-clear real-time video feeds, providing operators with a clear view of the monitored processes.

The remote monitoring capability of the system is a significant advantage, enabling operators to access and control the process from a safe distance, minimizing the risk of exposure to high temperatures. The system also includes data logging features, allowing the collection and analysis of historical data, facilitating trend identification, and the early detection of potential issues.

Another critical feature is the customizable alarm functionality, which alerts operators promptly to essential events or deviations in temperature, ensuring timely responses to prevent process disruptions or hazards. The robust construction of the camera system, using industrial-grade materials, guarantees durability and longevity even in challenging environments.

The High-Temperature Thermal View Furnace Camera System is complemented by the powerful and user-friendly InfraView software. This software provides real-time data visualization, offering live feeds of thermal and visual images with adjustable settings for better analysis. It also enables operators to review and analyze historical data, facilitating process optimization and identification of areas for improvement. Additionally, the software allows users to generate custom reports summarizing process performance and anomalies, and it can be seamlessly integrated with existing process control systems for streamlined data exchange.

With applications spanning industries such as steel, glass, cement, ceramics, and more, this furnace camera system is vital in facilitating process optimization, improving product quality, and enhancing overall safety by enabling operators to monitor critical industrial processes closely.

In summary, the High-Temperature Thermal View Furnace Camera System and the InfraView software are game-changers for industries operating in high-temperature environments. Its advanced features, remote monitoring capabilities, and real-time data analysis capabilities contribute significantly to improved efficiency, heightened safety, and optimized industrial processes.

Product Features

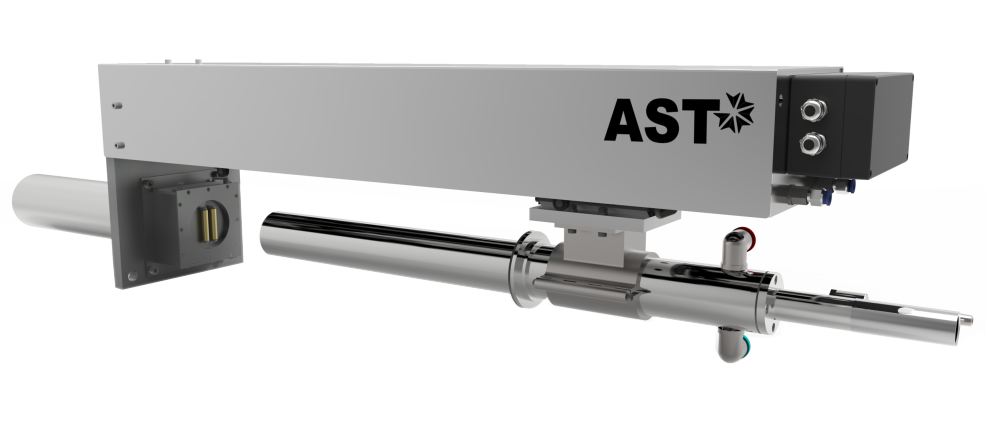

- Water-cooled lens tube, vortex-cooled camera chamber

- Auto retraction & Gravity shutter

- Pneumatic Rodless cylinder

- Air purge with Wall Sleeve

- Control Panel with pneumatic system

- Available in straight view & elbow view

- Standard software Infraview

- Input/Output Module

- Compatible with plant DCS

- OPC Connectivity (optional)

Infraview Software

- Configurable ROI’s: point, line, free shape

- Histogram and isotherm visualization

- Hot and cold spot detection

- Color pallet scaling

- Trend charts

- Alarm output

- Video and Image export

- Server client configuration

Applications

- Steel Industry

- Cement Industry

- Glass Industry

- Power Industry

- Waste Burning Industry

- Paper & pulp Industry

- Petrochemical & Refining Industry

- Incinerators

- Research & Development