Allows for increased extrusion speed

Better profiles, reduces amount of scrap produced

Saves gas or electricity at the Die Furnace, Billet Furnace, and Container electrical element.

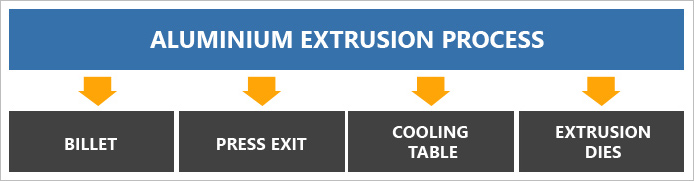

Installation of AST Pyrometers for Billet temperature measurement

The aluminium profiles are typically extruded at extrusion speeds in the range of 5 – 50 m/min depending on the alloy used and the profile complexity. Entry of overheated or under heated billets to the container controls the speed, quality, and wastage. As extrusion speed is increased productivity is increased. For example, if aluminium profiles are usually extruded at a low temperature of 520°C and the extrusion temperature is increased to 560°C, the extrusion press speed can be dramatically increased.

When profiles are extruded at very high temperatures, for example between 580°C to 600°C, product may be damaged. AST pyrometers can prevent this damage. AST customers report increased productivity rates of 5 – 10%.

Based on the intended use of the aluminium profiles, they are required to have different mechanical properties such as strength and hardness. These properties are achieved in two operations. The first one involves cooling of profiles in the extrusion process through the proper temperature adjustment and other one being control of extrusions leaving the die.

The A5-IN pyrometer have been developed for use in the aluminum forging industry. Unlike contact probe A5-IN pyrometer, will measure temperature within less than a second, and therefore is the most suitable instrument for forging application. Furthermore, non-contact pyrometer enables automatic, continuous, maintenance free temperature measurement. Non-contact temperature measurement provides accurate consistent reliable reading, which can be recorded (via RS-232 communication or Analog 4-20mA), for quality assurance purposes.

Accurate measurement of aluminium parts during forging process is vital to ensure quality product. It is well established that even minor changes in the billet temperature can cause deterioration in the mechanical properties of the forged part, by creating internal stresses and deformations. For that reason, AUTOMOTIVE PARTS MANUFACTURERS demand accurate measurement of each forged billet coming in and out the press.

Exit From Furnace

Recommended Product

A5-IN

Entry to Forging Press

Recommended Product

A5-IN

Exit from Forging Press

Recommended Product

A5-IN

The pyrometer can be installed on a linear motion scanning motor in order to measure and improve the temperature distribution uniformity of the billet. Data can be collected and analysed through Analog or Digital outputs.

The measurement of the temperature of the Aluminium Billet in the Forging process is an important parameter affecting the physical and mechanical properties of the product. Therefore, when safety involved measurement of the temperature of each piece is necessary and mandatory.

Wire Production

Recommended Product A5-IN

For the measurement of Aluminium Strip Bars, Rods and Wire

Coiled Rod Temperature measurement

Recommended Products: A5-EX

Strip Bars and Rods

Recommended Products: A5-IN, A5-S-IN & A5-S-EX

Recommended Products: A5-EX

Recommended Products: A5-EX

Importance of Temperature Measurement in Aluminium Cold Rolling Mill Non-contact measurements are important because it is not possible to touch with a thermocouple the metal moving continuously at a high speed during the rolling process. Moreover, even if it is possible to interrupt the rolling process for manual measurement of the slab or thick strip, this cannot be carried out during the final passes and coiling due to the process specification. Even when it is possible to stop the strip, there is a delay in the process and a reduction in the line productivity. For example, to monitor the slab or strip temperature at the start of the process the mill has to be stopped and the thermocouple mechanically positioned. At least 10 sec will be needed for the measurement. This results in at least a delay of 20-25 sec. However, the temperature needs to be measured and the optimum choice for this application is the non-contact infrared thermometer. Infrared sensors have been tried many times but with only limited success on aluminium because of the low and variable emissivity. The Accurate Sensor Technologies, Israel have successfully developed an infrared temperature measurement system that uses multiple wavelengths and complex algorithms to accurately measure the temperature in the Extrusion and Hot Rolling of aluminium alloys. The AST pyrometer has the option to store different calibrations in different groups in the processor memory and it is possible to switch between groups by a signal from an external PLC.

Recommended Products: A5-EX

European Aluminium Casting Producer produces castings of aluminium alloys for the automotive industry. In their foundry the alloy is melted in one furnace and transferred to a holding furnace before a controlled amount is fed into a casting crucible along a launder.

Measurement of temperature of the metal during the transfer from the casting crucible to the die is crucial at this stage for maintaining the homogeneous quality of the casting.

Our experience suggests that an immersion thermocouple cannot be used for this application. Temperature measurement using a conventional single colour infra-red pyrometer can be a complicated task due to the low and varying emissivity factors and they assume a constant emissivity. AST A5-IN pyrometer has been developed for this specific application.

A5-IN should be installed approximately 1200 mm above the launder and aligned using the in-built laser. This gives a spot size of approximately 38mm at the point of measurement. The pyrometer is then connected to a laptop / PC running theSD3000 software used to set the specific pyrometer parameters, display the results graphically and log the results in an Excel format. This software is supplied with the pyrometer and can be used to fine tune the settings to improve the accuracy in any specific location. The unit is used in its plug and play mode for liquid aluminium.

The practical adverse site condition for such application is lot of heat will be generated by the liquid metal or by the heating/use of the gravity die. Withstanding such harsh atmosphere is a challenge for such application. By installing the Pyrometer A5-IN at certain angle and by using some bright reflective screen can protect from the radiated heat also Air-cooling jacket can be used.

A5-IN pyrometer measures over the full range 450-900°C without problems in a linear manner. User can cut lower readout by setting required threshold “T brightness min”. The lower temperature recorded can be set by adjusting the “T brightness min” Also with the use of Analog output 4-20mA/0-10V you can set any scale between 300 to 1000C. General question from the users are whether this system can be used as a portable unit. Generally, it is not a mobile device, (weighs 3.5kg) and needs constant power supply of 24V DC. A suitable mounting system could be designed to enable two different measurement positions provided the cable connections to the unit are long enough. It is also possible to have a paired Bluetooth device for Pyrometer –PC wireless communication (standard device provide up to 100m communication distance – in case when no obstacles) but the pyrometer will still need the 24V supply. A5-IN with SD3000 software provides the facility to record the two readings temperature and emissivity under one sequence number in EXCEL file.

+91 9358443001

enquiry@astinfrared.com

© 2024 Accurate Sensing Technologies – All Rights Reserved

"*" indicates required fields